Pre-start checks are a critical aspect of overhead crane operations, ensuring both safety and compliance with industry standards. These checks are not just a best practice; they are a regulatory requirement designed to protect operators, equipment, and the surrounding environment.

Why are pre-start checks necessary?

Overhead cranes are essential in industries such as manufacturing, construction, warehousing, steel, transport and more. However, improper use or unnoticed faults can lead to serious accidents or operational delays. Pre-start checks serve as the first line of defense against potential hazards by:

- Ensuring Operational Readiness

Regular pre-start checks verify that the crane and its components are functioning correctly. By identifying and addressing issues like unusual noises, visible wear, or mechanical damage, operators can prevent unexpected breakdowns during use. - Compliance with Regulations

Industry regulations mandate pre-start checks to maintain workplace safety. Adhering to these requirements demonstrates your commitment to compliance and ensures that your business avoids costly fines or penalties. - Minimizing Downtime

Identifying faults before operation reduces the risk of unplanned downtime. By addressing issues early, repairs can be scheduled without disrupting productivity. - Extending Equipment Lifespan

Regular checks help identify wear and tear before it escalates into significant damage, prolonging the life of the crane and reducing long-term maintenance costs. - Supporting Routine Inspections

Information gathered during pre-start checks feeds into routine crane inspections. Reporting anomalies like wear, noise, or damage allows technicians to address problems systematically and ensures the crane remains in optimal condition.

Key elements of a pre-start check

Operators should follow a comprehensive checklist tailored to the specific crane and operational environment. While the exact items may vary, standard checks often include:

- Visual Inspection: Check for any visible signs of wear, damage, or corrosion on critical components such as ropes, hooks, and load chains.

- Operational Tests: Test controls, brakes, and emergency stop mechanisms to ensure they function correctly.

- Load Handling Equipment: Inspect lifting slings, hooks, and attachments for defects or wear.

- Noise Assessment: Listen for unusual sounds during operation that may indicate mechanical issues.

- Safety Features: Confirm that safety systems, such as overload sensors, are operational.

Building a safety culture

Incorporating pre-start checks into daily operations fosters a safety-first mindset among employees. Operators who understand the importance of these checks are more likely to report issues promptly, creating a safer and more efficient workplace.

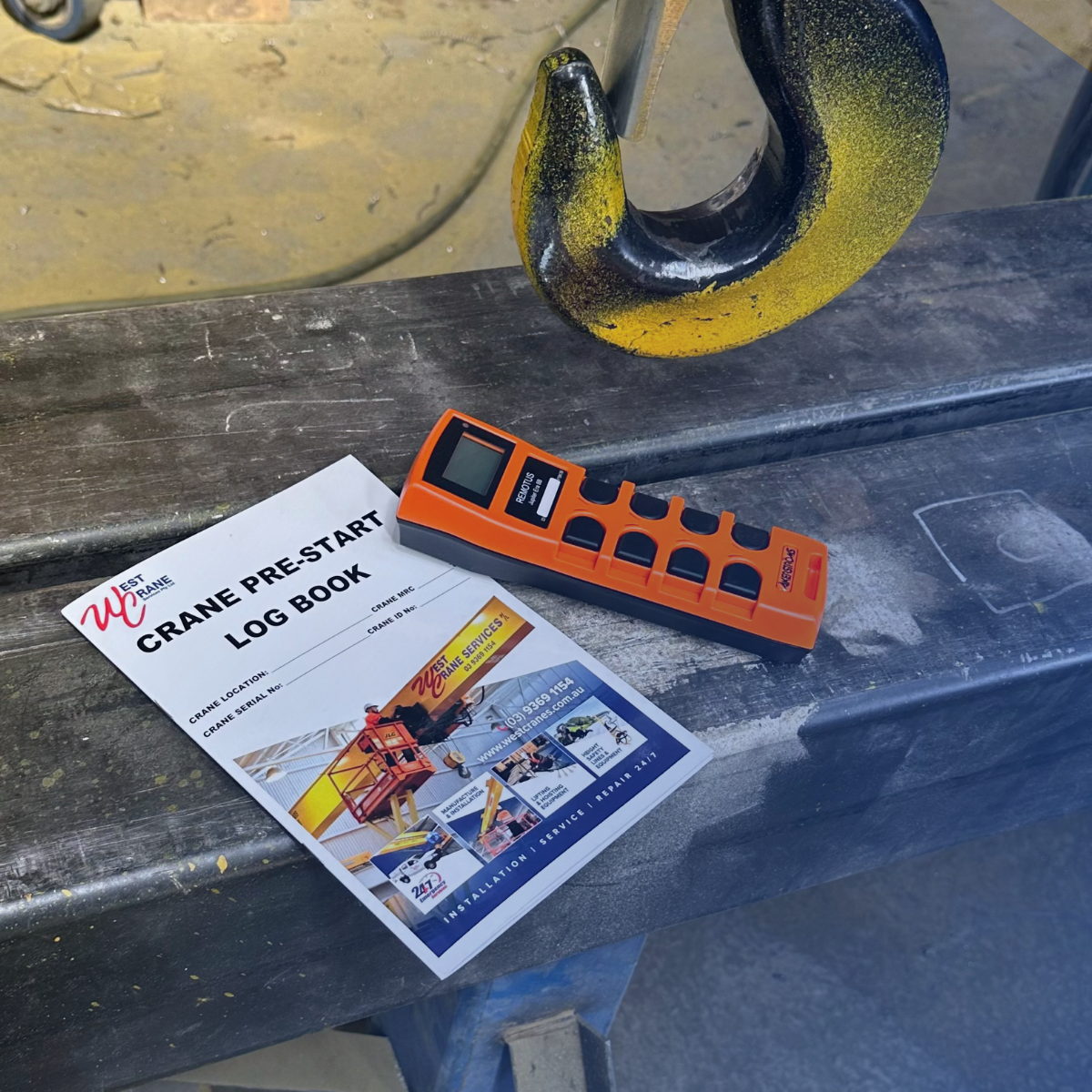

At West Crane Services, we emphasize the importance of pre-start checks as part of our comprehensive crane safety solutions. Our team is committed to helping businesses maintain compliance and ensure the safe operation of their overhead cranes.

24/7 Breakdown Service

24/7 Breakdown Service